Aohui Auto Parts Manufacturer – Alternators, Starters & AC Compressors Supplier

STARTERS & A/C COMPRESSORS

STARTERS & A/C COMPRESSORS MANUFACTURER

STARTER AND

A/C COMPRESSOR SUPPLIER

Featured Products Center

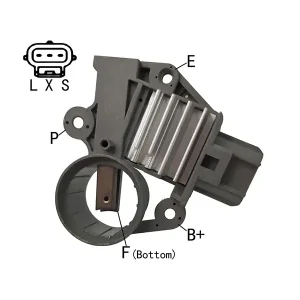

FORD Car Alternator Regulator F8WU10C359AB

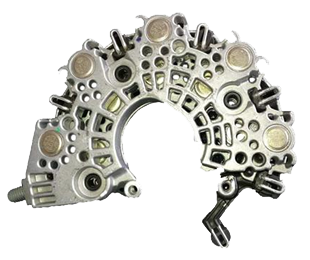

DENSO Car Alternator Rectifier 0215805300

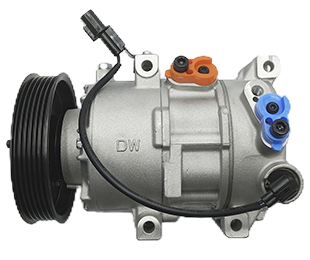

KIA Car Air Conditioning Compressor Assembly

BOSCH Car Alternator Rectifier F00M599507

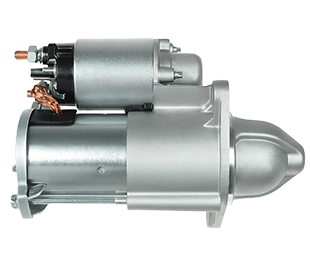

CHEVROLET Car Starter Assembly 8000387

AUDI Car Alternator Assembly DRA1278 LR1180851

MITSUBISHI Car Alternator Assembly DA2114N

BUICK Car Air Conditioning Compressor Assembly

Shop by Category

Car Alternator

Supplies stable electrical power to vehicle systems and charges the battery during engine operation.

Select Brand & Type

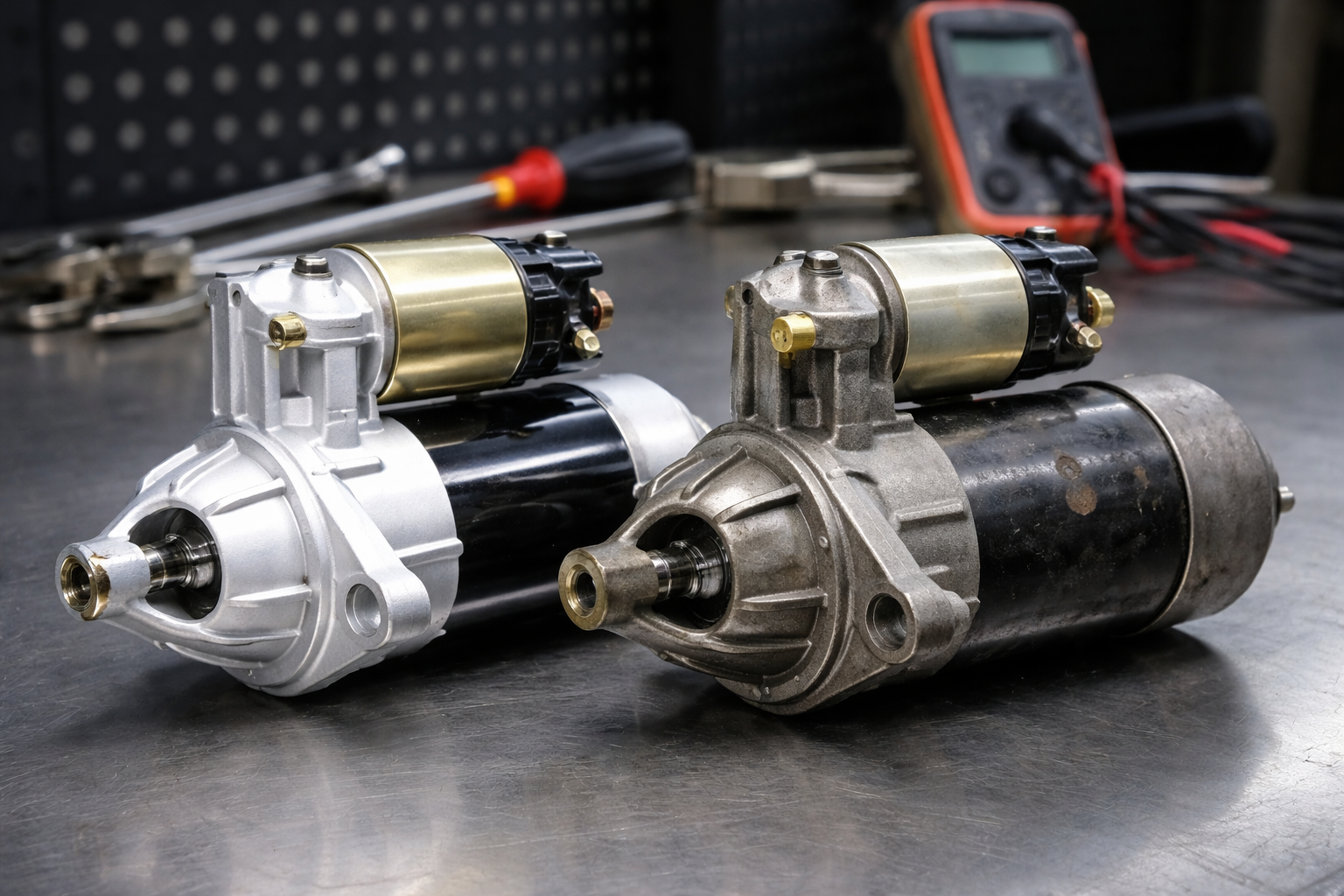

Car Starter

Delivers dependable engine ignition with high torque, ensuring fast starts in diverse conditions.

Select Brand & Type

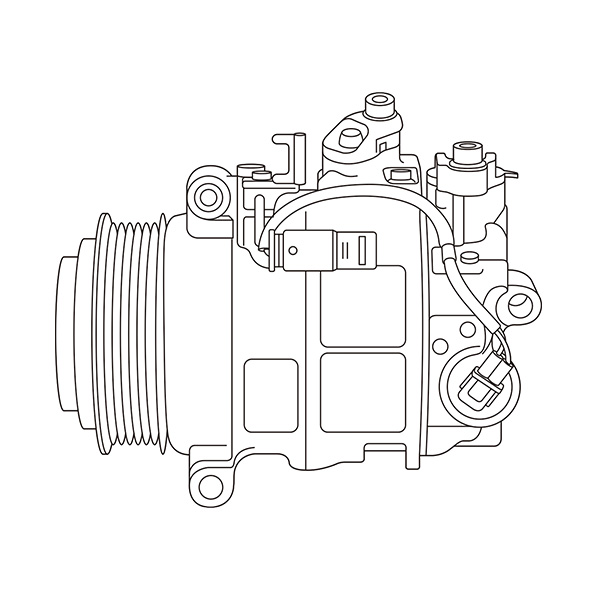

Car Compressor

Ensures effective air conditioning, delivering reliable cooling performance for consistent cabin comfort.

Select Brand & Type

About Us

Hebei Aohui Auto Parts Co., Ltd. is a professional development, production of various compressors, starters, generators and accessories enterprises. The company has more than 10 professional and technical personnel of auto parts, the introduction of the most advanced testing equipment at home and abroad, and has accumulated rich technical experience in product development and production. After years of development, our products have sold well all over the country.

Survive on Quality, Develop on Reputation,

Produce First-class Products and Provide First-class Service.

Lastest News

Car Starter Replacement: What You Need to Know for Reliable Starting

Car starter replacement becomes necessary when the starter motor can’t reliably crank the engine. A weak starter can create intermittent no-start situations that look like a battery problem—until you’re stranded. This guide explains how to recognize starter failure, confirm the cause, choose the right replacement, and avoid common installation mistakes—without guessing at costs. Starter Basics: What the Starter Motor Actually Does The starter motor turns the engine over fast enough for combustion to begin. When you turn the key (or press Start), the system typically involves: Battery power supplying current Starter relay/solenoid engaging the drive gear Starter motor cranking the engine Ignition/fuel systems taking over once the engine fires A problem anywhere in this chain can mimic starter failure, so accurate diagnosis matters before you commit to a car starter replacement. Signs You Need a Car Starter Replacement Starter issues are usually repeatable patterns, not random bad luck. Watch for: No crank (nothing happens) when you turn the key Slow crank even with a charged battery Single click or rapid clicking with no engine turnover Intermittent starting (starts fine, then won’t) Grinding sound during start attempts (engagement problem) A hot electrical smell after repeated start attempts (overheating/wiring load) If these symptoms happen more than once, treat it as a reliability problem—not a “wait and see” situation. Starter vs Battery vs Alternator: Quick Troubleshooting Before Replacement Many starting problems that look like a failing starter are actually caused by charging or battery issues. If you’re unsure which component is responsible, understanding the difference between starter and alternato can help you avoid replacing parts unnecessarily and focus on the real failure point. What it looks like vs what it often is Symptom during start Common cause What to check first Rapid clicking, no crank Weak battery / poor terminals Battery charge, terminal corrosion, ground strap Slow crank, lights dim Battery weak / high resistance Battery test, cable condition, chassis ground No sound at all Relay/ignition switch/neutral safety Starter relay, fuses, park/neutral switch One solid click, no crank Starter solenoid/motor Voltage at starter, solenoid signal wire Starts after tapping starter Starter internal wear Worn brushes/commutator inside starter If the battery tests good, cables are clean/tight, and the starter receives proper power and signal but won’t crank, car starter replacement becomes the most reliable fix. What Affects Car Starter Replacement Decisions Even if you don’t publish pricing, you should still answer the “cost intent” by explaining what drives the complexity and outcome: Starter accessibility Some starters are front-and-center; others are buried under intake components or near exhaust parts. Access affects labor time, risk of broken fasteners, and repeatability. Engine layout and heat exposure High heat can accelerate wear in wiring, solenoid contacts, and internal components—making reliability more sensitive to part quality and installation. Electrical condition of the vehicle A weak battery, corroded grounds, or voltage drop can damage a new starter over time. Fixing the root electrical issue protects the replacement. New vs rebuilt starter choice Quality depends on the manufacturer/remanufacturer standards and testing process more than the label alone. This section helps you rank against “cost pages” without publishing specific amounts—because you’re still satisfying the underlying intent. Choosing the Right Car Starter Replacement: New vs Rebuilt The “best” starter is the one that matches your vehicle and survives your usage pattern (cold starts, short trips, frequent stops, high-heat conditions). New starter replacement Choose new when you want: Maximum expected service life (model-dependent) Consistent manufacturing and warranty handling Lower risk in high-demand use (delivery fleets, frequent starts) Rebuilt (remanufactured) starter replacement Choose rebuilt when you prioritize: Practical value and reduced waste Availability for older models Strong performance if reman standards are proven What makes a rebuilt starter reliable? Look for evidence of: Replacement of wear components (brushes, bushings/bearings, solenoid contacts) Electrical load testing and engagement testing Clear warranty terms and traceable sourcing A rebuilt starter can be a strong option when it’s properly remanufactured and tested—not just cleaned and resold. Is Car Starter Replacement DIY-Friendly? Car starter replacement can be a reasonable DIY job on some vehicles—but difficult or risky on others. Use this decision table: DIY factor What “DIY-friendly” looks like Red flags (pro recommended) Access Starter visible, minimal components removed Buried under intake/exhaust, tight clearance Tools Basic sockets, extensions, jack stands Special tools, seized bolts, limited workspace Safety Clear battery isolation, stable support points Difficult lift points, limited support, near hot exhaust Electrical confidence Comfortable with terminals & routing Unsure about wiring, corrosion repair needed If you’re unsure, a professional approach reduces risk of: Cross-threaded bolts or misalignment Damaged wiring/terminals Incorrect torque leading to repeat failures Persistent no-start caused by misdiagnosis How Professional Car Starter Replacement Works (Step-by-Step) Professional starter replacement is usually structured to prevent electrical damage and repeat failures: Step 1: Confirm diagnosis before parts Battery and charging system check Voltage drop inspection on cables/grounds Starter signal verification (relay/solenoid command) Step 2: Isolate power correctly Battery disconnect (and memory-saving procedure if needed) Protect terminals and nearby wiring from shorting Step 3: Remove the old starter safely Access removal (shields, ducts, brackets as required) Disconnect wiring carefully (avoid twisting terminals) Remove mounting bolts without damaging threads Step 4: Install the replacement starter correctly Ensure mounting faces are clean and aligned Verify wiring routing isn’t pinched or heat-soaked Tighten fasteners correctly to prevent vibration issues Step 5: Post-install checks Start test (listen for clean engagement, no grinding) Inspect for heat contact, loose cables, abnormal draw Re-check grounds if intermittent cranking remains This is where your content can beat forum threads: you’re giving a repeatable, professional-safe workflow. Common Mistakes That Cause Repeat Starter Problems Even a good starter replacement can fail early if these issues aren’t addressed: Skipping cable/ground inspection Corrosion increases resistance, causing slow crank and overheating. Replacing starter without confirming battery health A weak battery can mimic starter failure and stress the new unit. Loose power cable or solenoid terminal Heat buildup and intermittent cranking often follow. Grinding ignored after replacement Grinding can indicate alignment/engagement issues that will damage the flywheel.

New vs Remanufactured Starter and How to Choose the Right One

Choosing between a new vs remanufactured starter sounds simple—until you’ve had a “no-start” morning, replaced the part, and the problem returns. The truth is: both options can be reliable, and both can disappoint, depending on how the unit was built, how the vehicle is used, and whether the underlying electrical conditions are healthy. This guide breaks down the real differences, why experiences vary so much online, and how to make a confident decision without guessing. What the difference is between a new and a remanufactured starter Before comparing new vs remanufactured starter, it helps to define terms the same way. New starter hEaQ11m&U7f#Y2QqKZ. Remanufactured starter A remanufactured starter is rebuilt from a used “core” in a factory-style process—typically disassembled, inspected, cleaned/machined as needed, then reassembled with replaced wear components and tested for function. The key detail is that remanufacturing standards vary by source, which is why results vary. Rebuilt vs remanufactured Naming varies by supplier, but a Rebuilt Starter and a remanufactured starter commonly refer to a core-based unit restored with replaced wear parts and functional testing, so evaluate the rebuild process and test standards rather than the label. Why experiences with remanufactured starters vary so widely If you search new vs remanufactured starter, you’ll see two extreme opinions: “Reman is just as good as new.” “Reman fails again and again.” Both can be true—because the outcome depends on a few variables: 1 Rebuilt vs remanufactured Naming varies by supplier, but a Rebuilt Starter and a remanufactured starter commonly refer to a core-based unit restored with replaced wear parts and functional testing, so evaluate the rebuild process and test standards rather than the label. New vs remanufactured starter performance considerations Instead of focusing on labels, focus on what affects day-to-day reliability. Reliability consistency New starter tends to be more consistent “out of the box.” Remanufactured starter can be excellent when standards are strict, but consistency depends on process and core screening. Engagement, noise, and repeatability Grinding, harsh engagement, or repeated clicking often points to: installation alignment issues damaged ring gear/flywheel teeth solenoid performance issues wiring/voltage drop problems Downtime tolerance If your starter is difficult to access, doing the job twice is the real risk. Access difficulty often shifts the new vs remanufactured starter decision toward new simply to reduce repeat labor and downtime. Which option makes sense for different use cases This is where the decision becomes practical instead of emotional. When a new starter is the better choice Choose new when you want maximum predictability in situations like: daily drivers with frequent short trips and frequent starts extreme temperature conditions (cold starts or heat soak) commercial or fleet usage hard-to-access starter locations where repeat labor is costly long-term ownership plans where consistency matters When a remanufactured starter can be a practical option A remanufactured starter can make sense when: the vehicle is older and reliability needs are reasonable the starter is easy to access if replacement is ever needed again the reman source can clearly explain replacement and testing steps core return is straightforward and the original core is acceptable Common failure causes after starter replacement Even a good starter can fail early if the system issues remain. Battery and cable issues that increase resistance and heat Poor grounding and voltage drop causing slow crank and overheating Heat shielding and cable routing problems that raise operating temperature Installation alignment issues leading to abnormal engagement and wear This is why replacing the starter alone isn’t always enough to restore reliable starting. How to evaluate remanufactured starter quality before buying If you’re leaning toward remanufactured, this is the part that protects you from “bad batch” outcomes. What to verify Which wear components are replaced by default (not only “as needed”) What functional tests are performed before release How cores are graded and screened (reject standards matter) Core return requirements and acceptance rules Warranty terms (helpful, but not a substitute for process quality) Red flags to avoid “Inspected” with no mention of testing No clarity on wear-item replacement policy Inconsistent packaging or missing protective caps No explanation of core selection and rejection New vs remanufactured starter decision checklist Use this checklist to decide quickly: Starter access is difficult → lean new Frequent starts / uptime matters → lean new Access is easy and source is transparent → reman can work Electrical system condition is unknown → test battery/cables/grounds first Repeat failures happened before → fix voltage drop + lean new Final thoughts for reliable starting A new vs remanufactured starter decision is less about “which is better” and more about matching the option to your vehicle use, access difficulty, and tolerance for repeat downtime. If reliability is mission-critical or access is painful, new is often the safer match. If access is easy and remanufacturing standards are clear and tested, a remanufactured starter can be a practical, reliable option.

Difference Between Starter and Alternator: Functions, Key Differences, and Diagnosis Guide

When a vehicle fails to start or shows electrical issues, two components usually come to mind: the starter and the alternator. Although they are part of the same electrical system, they perform completely different jobs. Understanding the difference between starter and alternator helps you diagnose problems faster, avoid unnecessary repairs, and keep your vehicle running reliably. This guide explains how each component works, how they differ, common symptoms, and how to tell which one is failing. What the Starter Does The starter (or starter motor) is responsible for cranking the engine when you turn the key or press the start button. It pulls high current from the battery and uses it to rotate the flywheel, allowing the engine to start combustion. How the Starter Works Draws power directly from the battery Converts electrical energy → mechanical rotation Engages the flywheel for only 1–3 seconds Stops working as soon as the engine starts Common Starter Failure Symptoms Clicking sound when turning the key Grinding noise or slow cranking Dashboard lights on, but engine does not rotate Jump-starting does not help if the starter itself is bad What the Alternator Does Once the engine is running, the alternator takes over. It generates electricity to power lights, sensors, ECUs, and accessories while continuously recharging the battery. How the Alternator Works Driven by the engine belt Converts mechanical energy → electrical energy Supplies steady power to all electrical systems Recharges the battery during driving Common Alternator Failure Symptoms Battery warning light on while driving Dimming headlights or flickering dashboard lights Weak battery even after charging Electrical accessories acting erratically Engine stalls after the battery drains Starter vs Alternator: Key Differences at a Glance Feature Starter Alternator Main Function Cranks the engine Generates power & charges battery Energy Conversion Electrical → Mechanical Mechanical → Electrical Works When? Only during startup Continuously while engine runs Depends On Battery Belt system & rotor Failure Symptoms Clicks, no crank, grinding Dimming lights, battery drain If It Fails Engine won’t start Vehicle dies while driving This table summarizes the difference between starter and alternator clearly for quick reference. How the Starter and Alternator Work Together The battery, starter, and alternator form a closed loop: Battery sends power to the starter Starter cranks the engine Engine begins running Alternator generates electricity Alternator recharges the battery Battery provides power for the next start If any part of this chain fails, the others may appear to fail as well—especially when a weak alternator causes a weak battery. How to Tell If It’s the Starter or the Alternator Use this simple three-step diagnostic method: Step 1 — Observe What Happens When You Start the Car No crank + clicking → Starter or battery Cranks slowly → Weak battery or failing starter Starts normally but dies while driving → Alternator Step 2 — Perform the Light Test Turn on headlights Try to start the engine Watch the lights: Lights dim heavily → Battery / Alternator problem Lights stay bright but engine doesn’t crank → Starter problem Step 3 — The Simple Jump-Start Test If jump-starting works → Alternator or battery issue If jump-starting does NOT help → Starter issue Is an Alternator the Same as a Starter? No — the alternator and starter are completely different components: The starter turns the engine on. The alternator keeps the vehicle powered after the engine is running. The starter only works for a few seconds; the alternator works continuously. Causes of Starter and Alternator Failure Starter Worn solenoid Damaged pinion gear Weak battery causing insufficient current Corroded terminals Alternator Worn brushes or bearings Belt slipping Overheated diodes High electrical load over long periods When to Replace Each Component Replace the Starter When: You hear frequent clicking The engine does not turn despite full battery Jump-starting has no effect Replace the Alternator When: Battery keeps draining Lights flicker while driving Battery warning light stays on Vehicle stalls during operation Why Understanding the Difference Matters Knowing the difference between starter and alternator helps you: Avoid misdiagnosis Prevent unnecessary repairs Understand warning symptoms earlier Extend vehicle lifespan Communicate more clearly with technicians FAQs 1. Can a bad alternator cause starting problems? Yes. A failing alternator cannot recharge the battery, leaving it too weak for the starter to operate during the next start. 2. What are the signs of a failing starter motor? Clicking, grinding noises, or the engine not cranking even when dashboard lights work normally. 3. How long do starters and alternators usually last? Most starters and alternators last 80,000–150,000 miles depending on driving conditions and electrical load. 4. Does jump-starting help diagnose the problem? Yes. If the car starts after a jump, the issue is likely the alternator or battery. If not, the starter is likely faulty. 5. Are battery issues often mistaken for starter or alternator failure? Yes. A weak battery can mimic both, so voltage testing is recommended before replacing any component. Conclusion The starter and alternator serve completely different but equally essential functions. The starter initiates engine rotation, while the alternator generates electrical power to keep the vehicle running. By learning the difference between starter and alternator and recognizing common symptoms, you can diagnose issues more accurately and maintain a more reliable vehicle.